- I. Core Kuiswa: Kudzora Mazano Akakosha muSystems

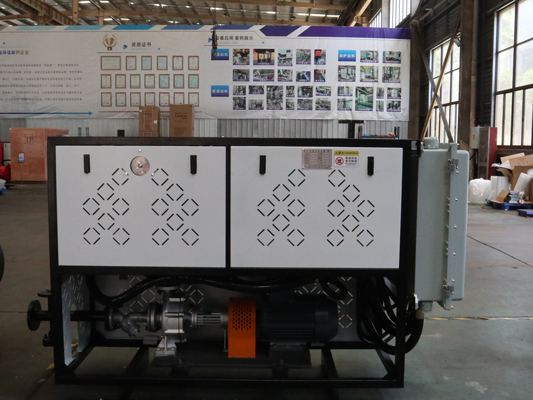

1. Main Muviri Kuiswa: Iva nechokwadi chekugadzikana uye Uniform Loading

Kukwirisa: Shandisa mwero wemweya kuti utarise hwaro hwechoto kuti uone kuti kuchinjika kwakamira uye kwakatwasuka kuri ≤1‰. Izvi zvinodzivirira kurereka kunogona kukonzera kusaenzana kurema pamachubhu echoto uye kuyerera kwakashata kwemafuta ekupisa.

Kuchengetedza Method: Shandisa anchor bolts (mabhoti maratidziro anofanirwa kuenderana nebhuku rekushandisa). Simbisa zvakaenzana kudzivirira base deformation. Kune skid-yakaiswa michina, ita shuwa kuti skid yakanamirwa zvakasimba pasi uye haina kuzununguka.

Accessory Inspection: Usati waiswa, calibrate valve security (set pressure inosangana nezvinodiwa zvekugadzira, zvakadai se 1.05 times the operating pressure) uye gauge yekumanikidzika (renji 1.5-3 nguva yekushanda kwekushanda, kururamisa ≥1.6), uye kuratidza chinyorwa chakasimbiswa. Thermometers inofanira kuiswa pane inopisa mafuta inlet uye pombi dzekubuda kuti ive nechokwadi chekutarisa.

2. Kuiswa kwePiping System: Kudzivirira Kudonha, Kuvhara Gasi, uye Coking

Material uye Welding:Mapaipi emafuta ekupisainofanira kugadzirwa nepamusoro-tembiricha inodzivirira seamless simbi pombi (senge 20# simbi kana 12Cr1MoV). Mapaipi ane galvanized anorambidzwa (iyo zinc layer inoputika nyore pakupisa kwakanyanya, zvichitungamira kukubika). Welding inofanira kuitwa uchishandisa argon arc welding for the base uye arc welding yebutiro. Majoini eWeld anofanirwa kuita 100% radiographic test (RT) ine pass level ye ≥ II kudzivirira kudonha.

Pipeline Layout:

Pipeline Slope: Thepombi yemafuta ekudzoka kwemafutainofanira kuva nemateru e ≥ 3 ‰, inotsvedza yakananga kutangi remafuta kana kuburitsa mvura kudzivirira kuunganidzwa kwemafuta enzvimbo uye kubika. Kutsetseka kwepombi yekubuda kweoiri kunogona kudzikiswa kusvika ≥ 1‰ kuve nechokwadi chekuyerera kwemafuta.

Exhaust uye Drainage: Isa chivharo chekupedza simba panzvimbo yakakwirira yepombi (yakadai sepamusoro pechoto kana pabend) kudzivirira kuungana kwegasi muhurongwa, izvo zvinogona kukonzera "kuvharwa kwegasi" (localized overheating). Isa chivharo chekudhonza panzvimbo yakaderera kuti ufambise kuchenesa nguva dzose kwetsvina uye kubika. Dzivisa mabhendi akapinza uye kuchinja kwedhayamita: Shandisa mabhendi akakombama (radius of curvature ≥ 3 times the diameter diameter) pakubhenda kwepombi; dzivisa mabhendi ekona-kurudyi. Shandisa concentric reducers paunenge uchichinja madhayamita kudzivirira eccentric shanduko inogona kukanganisa kuyerera kweoiri uye kukonzera kupisa kwenzvimbo.

Kuisa chisimbiso bvunzo: Mushure mekuiswa kwepombi, ita bvunzo yekumanikidza mvura (yedzo yekumanikidza 1.5 nguva yekumanikidza kwekushanda, chengetedza kumanikidza kwemaminetsi makumi matatu, pasina kubuda) kana pneumatic pressure test (test pressure 1.15 times the operational pressure, chengetedza kudzvanywa kwemaawa makumi maviri nemana, kudonha kudonha ≤ 1%). Mushure mekusimbisa kuti hapana kuvuza, enderera nekuisa insulation.

Insulation: Mapombi nemitumbi yevira inofanira kuiswa insulation (ichishandisa yakakwirira-tembiricha isingachinjiki zvinhu zvakaita se rock wool uye aluminium silicate, ine ukobvu hwe ≥ 50mm). Fukidza nesimbi inodzivirira kudzivirira kurasikirwa nekupisa uye kupisa. Insulation layer inofanira kuvharwa zvakasimba kudzivirira mvura inonaya kuti isapinda mukati uye zvichikonzera kutadza kwekudzivirira. 3. Electrical System Installation: Kuchengetedza uye Precision Control

Wiring Zvido: Kabati yemagetsi inofanira kunge iri kure nekupisa uye mvura. Simba uye tambo dzekudzora dzinofanirwa kuiswa zvakasiyana (shandisa tambo-inodzoreredza tambo yetambo dzemagetsi). Materminals anofanirwa kusungirirwa zvakachengetedzeka kudzivirira mabhanhire akasununguka anogona kutungamira mukupisa. Iyo yepasi system inofanirwa kuve yakavimbika, ine kushorwa kwepasi kwe ≤4Ω (kusanganisira pasi pemidziyo pachayo uye kabati yemagetsi).

Kuputika-Uchapupu Zvinodiwa: Zvemafuta-akapisa / gasi-anopfurwathermal mafuta boilers,zvinhu zvemagetsi padhuze nembavha (sezvinoita mafeni nemavharuvhu e-solenoid) zvinofanira kunge zvisingapindike (semuenzaniso, Ex dⅡBT4) kudzivirira pfarivari kubva mukukonzera kuputika kwegasi.

Kudzora Logic Kutarisa: Usati watumira, simbisa schematics yemagetsi kuti uone kuti tembiricha yekudzora, kudzivirira kudzvanywa, uye yakakwira uye yakaderera mvura maaramu ari kushanda nemazvo (semuenzaniso, kudzima otomatiki kwemafuta ekupisa kana kupisa kukaitika uye kupisa kwekutanga kunorambidzwa kana mwero wemvura wakadzikira).

II. System Commissioning: Simbisa Kuchengetedzeka mumatanho

1. Cold Commissioning (Hapana Kupisa)

Tarisa Pipeline Tightness: Zadza sisitimu nemafuta ekupisa (vhura vharafu yekuburitsa kuti udzinge mweya wese panguva yekuzadza) kusvikira iyo mafuta asvika 1/2-2/3 yetangi. Rega igare kwemaawa makumi maviri nemana uye iongorore pombi nemawelds emvura.

Edza iyo Circulation System: Tanga pombi yekutenderera uye tarisa iyo inoshanda ikozvino uye ruzha nhanho (ikozvino ≤ yakatarwa kukosha, ruzha ≤ 85dB). Ita shuwa kuti mafuta ekupisa anotenderera zvakanaka mukati meiyo system (bata mapaipi kuratidza kuti hapana nzvimbo dzinotonhora kudzivirira kuvharika kwemhepo).

Verify Kudzora Mabasa: Tevedzera zvikanganiso senge tembiricha, overpressure, uye yakaderera mvura mwero kuti uone kuti maalarm uye emergency shutdown mabasa ari kushanda nemazvo.

2. Kutumira Mafuta Anopisa (Zvishoma nezvishoma Temperature Inowedzera)

Heating Rate Control: Iyo yekutanga tembiricha yekuwedzera inofanira kunonoka kudzivirira kuwedzeredza kwenzvimbo uye kubika kwemafuta ekupisa. Zvakananga zvinodiwa:

Kupisa kwekamuri kusvika ku100 ° C: Kupisa kwekushisa ≤ 20 ° C / h (kubvisa unyoro kubva mumafuta anopisa);

100 ° C kusvika 200 ° C: Kupisa kwekushisa ≤ 10 ° C / h (kubvisa zvikamu zvechiedza);

200 ° C kusvika kune tembiricha yekushanda: Kupisa kwekushisa ≤ 5 ° C / h (kudzikamisa hurongwa).

Maitiro Okutarisa: Panguva yekudziya, nyatso tarisisa iyo yekumanikidza geji (pasina kuchinjika kana kuwedzera kamwe kamwe) uye thermometer (yetembiricha yeyunifomu pane ese mapoinzi). Kana paine kuzunguzika kwepombi kana tembiricha abnormalities (eg, localized overheating inopfuura 10°C) zvikaonekwa, pakarepo vhara choto kuti chiongororwe kubvisa chero kuvharika kwemhepo kana kuvharika.

Nitrogen Gasi Kudzivirirwa (Optional): Kana mafuta anopisa anoshandiswa pakupisa ≥ 300 ° C, zvinokurudzirwa kuunza nitrogen (zvishoma kudzvinyirira kwakanaka, 0.02-0.05 MPa) mutangi yemafuta kudzivirira oxidation kubva pakusangana nemhepo uye kuwedzera hupenyu hwayo hwebasa.

Kana iwe uchida kuziva zvakawanda nezvechigadzirwa chedu, ndapotataura nesu!

Nguva yekutumira: Sep-04-2025